Calf Housing

When selecting a calf housing system, you will need to consider your climate, budget, labour constraints and individual preferences. There is no single system that suits everyone’s needs. The impacts of a particular system on calf health and welfare also need to be considered. On this page you will find a comparison of different calf housing options, as well as some case studies that take an in-depth look at the options available.

Comparison of calf housing systems

This document provides an overview of the advantages and disadvantages of different calf housing systems.

-

Comparison of Calf Housing Systems factsheet

PDF, 2.54 MB

Case Studies

Calf housing does not have to be elaborate to be effective. This series of case studies takes an in-depth look at the calf housing options available to dairy farmers.

Case study: Lang family, Tatura, Victoria

Retro-fit conversion of a milking shed

The Lang family farm is located at Tatura, Victoria. The Langs took a five-year period to update this self-built shed, which was used as a milking shed until 1997. The project had a parts cost of $22,000.

This group housing system helps rear 260 calves per year in two batches; 70 in autumn and 160 in spring.

In the video below, Marcus Lang details the family operations and calf housing process.

-

Shed specifications

Shed structure

Materials used

- Galvanised iron on west wall and roof

- Plastic sheeting on east wall

- Cement flooring

Aspect

- Length of shed on east-west orientation

Dimensions

- 54.0 metres long x 9.0m wide x 4.4m high

Roof design

Pitch

- Difference in height/width: 90 centimetres in 9.0m

- Single pitch from west to east

Roof height

- Lowest point: 4.0m

- Highest point: 4.9m

Air space

Total air space

- 2,138 cubic metres

Air space per calf at peak

- 11.2m3

Ventilation

Type

- Passive

Cooling/airflow

- 6m wide gap in middle of west wall

- 3m wide gap in middle of south wall

- 3m wide gap in middle of north wall

- 2m wide plastic sheeting along the top of 24m of east wall

- Old building restricting air flow along 20m of east wall

Shed capacity

Maximum number of calves housed at peak

- 160 calves

Month of peak use

- September/October

Age of calves entering and leaving shed

- 0 to 24 hours. Calves are collected from the calving down area once each day.

Age/body weight of calves leaving shed (weeks/kilogram of body weight)

- Eight weeks of age, following weaning

Labour requirements (total man hours/day at peak use)

- Four man hours per day

Labour hours/50 calves at peak (total man hours/50 calves/day)

- 1.1 man hours/50 calves/day

Process

Calves are collected once per day after suckling dams for colostrum and an initial feeding of two litres of colostrum per calf.

The autumn configuration is to only use half the shed for rearing calves. This is 16 pens, each 3.0m x 3.5m in size. The rest of the shed is used for storing extra gates, troughs and teat feeders required for spring calf rearing.

The width of the aisle between the two batches of group pens, 2.0m, is only just sufficient for easy access and maneuvering of the bike and trailer carrying the milk from the dairy shed.

-

Pen specifications

Pen structure

Type

- Group pens (3.0m x 3.5m) for five calves

Wall height

- 800 millimetres. These are purpose-built gates.

Wall materials

- Solid/mesh

Front

- Gates with metal slots to join them. Removable for cleaning the shed.

Sides

- Gates with metal slots to join them. Removable for cleaning the shed.

Back

- Solid wall of west wall, gates with metal slots on east wall.

Process

Only half of the shed was fitted out for calf rearing since there were only 70 autumn calves, compared to 160 calves in spring. All pen gates can be easily removed to allow for complete cleaning of the calf shed, floor and walls using a pressure hose. Leaving the shed completely empty for several months between batches of calves also allows solar sterilisation of the shed.

Pen flooring

Type

- Concrete

Drainage

- Concrete slopes (0.5m in 24m) from north to south but there is no slope from east to west

Total floor space per pen

- 10.5 square metres

Floor space per calf at peak capacity

- 2.1m2 per calf

Bedding

Type

- Wood shavings

Minimum depth

- 150mm

Maintenance

- New wood shavings added weekly and entire bedding is removed following eight weeks of milk feeding.

Other

Soiled bedding is dumped in the manure pit at the bottom of the milking shed.

Feed and water

Milk feeding system type

- Teats in batches of five per pen

Milk delivery method

- Whole milk is transported from the milking shed in a tank located on a trailer and motorcycle

Hay

- In a hay rack in the middle of each pen

Pellets

- Calf muesli fed in a 2.5m-long trough in each pen

Water

- Water fed from a bucket, located inside a wheelbarrow tire for stability on the edge of each pen

Other

- Each calf is fed 3–4 litres of milk per day (twice daily) for three weeks then 3L/day (once daily) until weaning at 7–8 weeks of age

- Calves are offered ad-lib water and oaten hay from week one onward

- They are also fed calf muesli (20% protein) from week one onward with a gradual change over to calf rearing pellets (18% protein)

- They are weaned off milk once they are eating 1.5 to 2.0 kilograms of pellets per calf per day

- The calf pellets are stored in a silo, while the calf muesli is stored in bags.

-

Other infrastructure

Cleaning and disinfection

Type

- Lime is placed on the cement floor prior to covering it with new wood shavings

Other

- The calf shed has been located close to the farm house so the farm family can occasionally wander through it to check on calf health and welfare

Biosecurity

Boot/hand washing facilities

- No strict protocol, rely on common sense

Housing of sale calves

- Kept close to access road for once-weekly pickup by calf truck

Quarantine area for sick calves

- There are several calf igloos in which sick calves can be isolated away from the healthy calves

Colostrum management, record keeping system

- Eartags and date of birth of all calves and sick calves are recorded

Feed preparation and storage

Facilities (if in calf shed)

- Sink, fridge, storage cupboard, records/filing cabinet

Other

- Calves are fed pellets twice daily and pens with high intakes are noted for weaning off milk

Case study: Stuart Tweddle, Darum, Victoria

Hutches and igloos - biosecurity benefits

Stuart Tweddle milks 400 cows on a dryland farm located at Darum, Victoria. Stuart's calf housing system, using 40 hutches and two igloos, supports the farm's calving pattern of 300 calves per year, calving continuously from April to November. The project cost approximately $30,000.

-

Shed specifications

Shed structure

Construction materials

- Walls: polyethylene/plastic

- Roof: polyethylene/plastic

- Floor: sawdust on soil

- External yard: sawdust on soil

Aspect

- Hutches and igloo doors open to the north

Dimensions

- Hutches are 2,200 millimetres long x 1,300mm wide x 1,500mm high

External yard/calf paddock

- Hutches: 2,000mm x 1,400mm

- Igloos: 4,800mm x ~3,500mm (average)

Roof design

Roof openings (50-75mm/3m width)

- Ventilation to rear and on peak

Roof height

- Lowest point: 1,400mm

- Highest point: 1,500mm

Ventilation

Type

- Passive

Cooling/airflow

- Adjustable hatch to south side (opened fully in hot weather)

- Ventilation slots along top of roof

- Open door to the north

Shed capacity

Maximum number of calves housed at peak

- One per hutch (40 hutches)

- 10/igloo (two igloos)

Month of peak use

- April until September

Labour requirements (total man hours per day at peak use)

- 40 minutes to feed calves twice daily

Labour hours per 50 calves at peak (total man hours/50 calves/day)

- 80 minutes per 50 calves (including feed preparation)

Other

- Calves are brought up to the dairy 1–2 times daily and given colostrum and supplement (Kick Start), then tagged and taken to a hutch

-

Pen specifications

Pen structure

Type

- Individual until three weeks old then grouped in batches of 10

Wall height

- 1,500mm

Wall materials

- Weld mesh wall for hutch pens

- 4.2-metre gates for igloos

Pen flooring

Type

- Sawdust over pasture

Drainage

- Slight slope in paddock.

- Hutches put at the bottom of the slope first

- Some drainage lines cut in paddock

- New site for each calf

Total floor space per pen

- Hutch: 5.2 square metres

- Igloo: About 28m2

Floor space per calf at peak capacity

- Hutch: 5.2m2

- Igloo: 2.8m2

Bedding

Type

- Sawdust ($30 per cubic metre)

Minimum depth

- 75mm

Maintenance

- Hutch: Sawdust put in place then hutch put on top of this. No top-up required unless really wet. Hutch moved to new site for next calf

- Igloo: Sawdust put in place. Igloo added. New site per batch

- Other: Left to compost on-site. Limed and smudged at end of season

Feed and water

Milk feeding system type

- Milk taxi to individual calf feeder

- Calves given 2.5 litres of warm fresh milk twice daily

Milk delivery method

- Heated milk taxi (250L) pumped into feeders

Hay

- Hay basket hung off gates

Pellets

- Pellet trough inside igloo

Other

- 2.5L twice daily for all calves

- Ad-lib pellets and hay for calves over three weeks old

-

Other infrastructure

Cleaning and disinfection

Type

- Batch

Other

- New site and sawdust for each calf/batch

- Hutches and igloos scrubbed with Vircon at the end of the season

Biosecurity

Access restrictions

- Traffic kept to designated track along side/bottom of slope and away from calves

Housing of sale calves

- Kept in a separate shed at the front of the farm

Quarantine area for sick calves

- Treated in igloo (mortality to weaning less than 2%)

Other

- Given colostrum from fresh cow when first collected (within 24 hours of birth) and immunoglobulin supplement as soon as possible

- Use Queen of Calves probiotic/energy supplement in milk fed twice daily

Feed preparation and storage

Facilities

- Fresh milk at dairy heated in 250L milk taxi to 30 degrees Celsius and towed down to calf paddock

- Hutches and igloos supplied by Daviesway Warragul.

- Hutches are Calf-Tel Pro II

Case study: Chris and Charmaine Bagot, Jindivick, Victoria

Purpose-built, low-cost greenhouse barn

Looking for a low-cost calf rearing system, Jindicick, Victoria, farmers Chris and Charmaine Bagot opted for a self-built greenhouse barn/hot house shed. The structure is built mainly from recycled materials and cost about $5,000, excluding the second-hand DeLaval automatic calf feeder.

Between 150 and 180 calves are reared as one group per year, with older calves removed in batches to a separate farm once they are weaned. The Bagots have a seasonal autumn calving pattern. In this video, Chris explains his purpose-built shed, commenting on the build, maintenance and benefits of this system.

In this video, Paul explains the new shed he designed to comfortably house 700 calves and make life easier for those looking after them.

-

Shed specifications

Shed structure

Materials used

- Walls: tin and laser light (recycled)

- Roof: tin and plastic-domed greenhouse roof (plastic over three-quarter inch pipe)

- Floor: concrete under feeders and deep wood chips elsewhere

- External yard: pasture with shelter trees

Aspect

- East to west (wind from south-west)

Dimensions

- Structure: 24 metres long x 5.45m wide x 3.2m high (domed section), 24m long x 4.15m wide x 2.15m high (roofed section)

- External yard/calf paddock: 75m x 30m

Roof design

Pitch

- Difference in height/width: domed roof (5.45m wide and 1.05m high) and extension roof (4.15m wide and 0.2m fall) - 5% slope

Roof height

- Lowest point: 1.95m (south wall of extension)

- Highest point: 3.2m (domed roof)

Air space

Total air space

- Under greenhouse: 392 cubic metres

- Under extension: 202m3

- Total: 594m3

Ventilation

Type

- Passive, assisted by two fans under greenhouse roof if required

Cooling/airflow

- Tunnel designed to pick up breeze

- South wall: 800 millimetre x 2m gaps in wall at 760mm height

- North wall - 400mm gap in wall entire length

Shed capacity

Maximum number of calves housed at peak

- 150

Month of peak use

- March

Age of calves entering and leaving shed

- Zero to 12 hours old

Labour requirements (total man hours per day at peak use)

- 1.5 hours/day once all calves started

Labour hours per 50 calves at peak (total man hours/50 calves/day)

- 30 minutes/50 calves/day

Process

- Calves collected at least twice daily

- Iodine dip navel

- Probiotic paste

- Tagged

- Colostrum tubed if needed,

- Put in small pen to get started on auto feeder.

-

Pen specifications

Pen structure

Type

- Smaller pens for start-up (up to 15 calves) then into communal pen with access to paddock

Wall height

- 760mm (width of sheet of tin)

Wall materials

- Front: mesh to feeders, tin to paddock

- Sides: removable mesh/gates

- Back: bottom 800mm tin, laserlite to roof

Removable

- Side walls swing back to wall and can be removed for cleaning

- Solid concrete gutter for scraping against south wall

Pen flooring

Type

- Concrete for feeding area, deep wood chips over dirt for the rest

Drainage

- Sloped concrete to central drain (to effluent pond)

Total floor space per pen

- 231 square metres in shed

Floor space per calf at peak capacity

- 1.5m2 in shed but calves also have access to 2,250m2 in paddock

Other

- Feed and water kept on concrete area

Bedding

Type

- Wood chips

Minimum depth

- 300mm

Maintenance

- Replaced every 3–4 weeks through season

Other

- Composted then spread on paddocks

Feed and water

Milk feeding system type

- DeLaval automatic feeder

Milk delivery method

- Fourth line in dairy to refrigerated vat

- Pumped underground to calf shed

- Non-refrigerated vat in calf shed filled up every 2–3 days

- Automatic milk feeders draw from this

Hay

- Wire baskets hung from wall, 500mm high

Pellets

- DeLaval auto feeders filled up by bucket

Water

- Small drinking dishes on walls

- Piped water to clean-up/preparation area

-

Other infrastructure

Cleaning and disinfection

Type

- Continuous, run as a mob

Other

- Very low mortality rate

Biosecurity

Housing of sale calves

- All bull calves are kept

Quarantine area for sick calves

- Small pen next to calf shed (rarely used)

Other

- Book kept in shed next to feeders

- DeLaval reports and exception list checked daily

Feed preparation and storage

Facilities (if in calf shed)

- Wheel barrow to transport pellet buckets

-

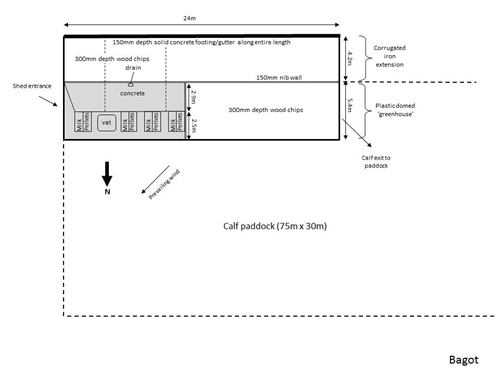

Layout

Layout of calf housing shed at Bagot.

Case study: Paul Bennett, Elizabeth Town, Tasmania

Purpose-built, open group housing – custom design and a standard kit

At Ashgrove Farm, located at Elizabeth Town, Tasmania, Paul Bennett rears 1,300 calves per year in two batches. For his calf housing system, Paul designed a purpose-built shed that could make use of standard gates and railings. The shed was built from a standard kit and the project cost was $150,000 all up.

In this video, Paul explains the new shed he designed to comfortably house 700 calves and make life easier for those looking after them.

-

Shed specifications

Shed structure

Construction materials

- Walls: colourbond on north and south ends. No walls on west and east sides

- Roof: colourbond with one-metre wide skylight every five metres

- Floor: concrete and dirt

Aspect

- Oriented north-south, providing sun in the morning and afternoon into calf pens

- Prevailing winds from the north-west

Dimensions

- Structure 70m long x 15m wide x 4.8m high

Roof design

Pitch (1:4)

- Difference in height/width: 15%

Overhang eves

- 1,000 millimetres

Roof height

- Lowest point: 3.4m

- Highest point: 4.5m

Air space

Total air space under roofline

- 4,200 cubic metres

Air space per calf at peak (6-8m3)

- 6m3

Ventilation

Type

- Passive

Cooling/airflow

- No walls along sides of shed

- Solid gates on windward side (west) to 1,200mm in height

Shed capacity

Maximum number of calves housed at peak

- 728 calves total

- Up to 26 calves per pen (mostly 23 to 25 calves per pen)

Month of peak use

- September

Age of calves entering and leaving shed

- 24 hours to 10 weeks of age

Labour requirements (total man hours per day at peak use)

- Two people x 1.5 hours per day

- A single person can feed 700 calves in an hour once all the calves are self-feeding

Other

- Calves brought in during early afternoon and tubed

-

Pen specifications

Pen structure

Type

- Group

Wall height

- 1,000mm

Wall materials

- Front: rails

- Sides: solid on concrete, two swinging sheep gates (2.15m) on bedding

- Back: two sheep yard panels, solid to west

- Removable: crush frame 'bows' concreted in

Pen flooring

Type

- Concrete and deep litter over dirt

Drainage

- Concrete drains to centre walkway (about 2% slope)

- Centre walkway drains to south end of shed (5% slope)

Total floor space per pen

- 35 square metres

Floor space per calf at peak capacity

- 1.35m2/calf

- Usually 23 calves per pen, so 1.5m2/calf

Bedding

Type

- Sawdust

Minimum depth

- 300mm

Maintenance

- Scrap out at end of season

- Completely replace between batches

Other

- Used bedding composted and given to gardeners

Feed and water

Milk feeding system type

- Teat feeders made to order

Milk delivery method

- Pumped from tank on trailer

Hay

- Wire net on fence

Pellets

- Ad-lib supply from hopper in each pen

- Fed by standard herringbone set-up from a silo into cut away 25-litre drum, 600mm off the floor

Water

- Nipples in each pen

Other

- 4.5L per calf (some over feed)

- Feeders have a mark in to ensure staff give the correct amount

-

Other infrastructure

Cleaning and disinfection

Type

- Batch

Other

- Aim to move batches further apart once CSD is shifted

Biosecurity

Boot/hand washing facilities

- Hose at northern end of shed

Housing of sale calves

- All calves are reared, including males

Sick calves quarantine pen

- Moved to bottom pen (very few problems)

Other

- Colostrum tube fed twice in first 24 hours

- Records kept on whiteboard in shed and in note book

- No tags on calves at this age

Feed preparation and storage

Facilities (if in calf shed)

- Portico to be built at northern end of shed for storage

Case study: Nigel Brock, Montana, Tasmania

Purpose-built, low-cost, free-standing sheds

Nigel Brock is based at Montana, Tasmania. His calf housing system features eight purpose-built sheds for 30 calves per shed.

The project cost him $15,000 for fencing, plus eight home-built sheds at $2,000 each. The farm's calving pattern is seasonal, rearing 240 calves per year.

In this video, Nigel talks about the low-cost solution he devised to house his calves.

-

Shed specifications

Shed structure

Construction materials

- Walls: corrugated iron on timber frame

- Roof: corrugated iron on timber frame

- Floor: sawdust over soil

- External yard: pasture

Aspect

- Facing east

Dimensions

- Structure: Each shed is six metres long x 3m wide x 2.5m high (18 square metres)

- External yard/calf paddock: 22m x 200m for each shed (4,400m2)

Roof design

Pitch

- Difference in height/width: 0.5m:3m = 1:6 (single slope to rear)

Roof height

- Lowest point: 2m

- Highest point: 2.5m

Air space

Total air space

- Inside only – 42 cubic metres

Air space per calf at peak

- Inside only – 1.4m3

Ventilation

Type

- Passive

Cooling/airflow

- Open on east wall

Shed capacity

Maximum number of calves housed at peak

- 30 per shed

- 240 calves across eight sheds

Month of peak use

- August/September

Age of calves entering and leaving shed

- Enter at seven to 10 days old

- Leave at 12 weeks old

Labour requirements (total man hours per day at peak use)

- One hour per day to feed 240 calves with one 450-litre Calfateria feeder

A 1,000L tank to be installed at site to avoid towing Calfateria back to main dairy twice a day for each feeding

-

Pen specifications

Pen flooring

Type

- 150mm of sawdust

Total floor space per pen

- 18 square metres

Floor space per calf at peak capacity

- 0.5m2 (internal)

Other

- 4,400m2 per 30 calves

Bedding

Type

- Straw, shavings, chips, sand

Minimum depth

- 150mm of sawdust

Maintenance

- Top-up at start of the season

Feed and water

Milk feeding system type

- 450L Calfateria does three batches

- 5L/calf per day

Milk delivery method

- Calfateria transport to paddock

- Installing a 1,000L tank on ute to transport milk from dairy to calf paddock

Hay

- Wire net on fence

Pellets

- Troughs

Water

- Trough in paddock

-

Other infrastructure

Cleaning and disinfection

Type

- Single batch only on the area then rested for eight months until next season

Other

- Sheep graze the area when calves are not using it

Biosecurity

Access restrictions

- Try not to drive vehicle into paddocks (except with Calfateria)

Housing of sale calves

- In a shed at the dairy

Quarantine area for sick calves

- Taken back to a shed near the dairy

Case study: Dornauf Dairies, Elizabeth Town, Tasmania

Purpose-built, centralised group housing with computer-controlled feeders

Dornauf Dairies runs four farms at Elizabeth Town, Tasmania. Centralising the dairy's calving system helped reduce labour requirements and increase both biosecurity and calf comfort.

This purpose-built shed was provided as a kit from a local shed builder. The dairy rears between 550 and 600 calves per year, with a calving pattern of 150 to 180 in autumn (April/May) and 400 in spring (August/September).

In this video, Chris Dornauf gives a walk-through of his purpose-built shed that houses 400 calves and features computer-controlled feeders for both milk and grain.

-

Shed specifications

Shed structure

Construction materials

- Walls: zinc aluminium

- Roof: zinc aluminium and skylights

- Floor: concrete/gravel

- External yard: pasture

Aspect

- Facing west to east

- Wind from north-west

Dimensions

- Structure: 42 metres long x 20m wide x 5m high (4.2m at eaves)

- External yard/calf paddock: 12 x 0.3-hectare areas

Roof design

Pitch

- 8% (1:12.5)

Roof height

- Lowest point: 4.2m

- Highest point: 5m

Air space

Total air space

- 3,780 cubic metres

Air space per calf at peak

- 9.45m3

Ventilation

Type

- Passive through open doors

Cooling/airflow

- Three large roller doors to west

- One large roller door (3m) to east

- Six small roller doors (2m) to sides

Shed capacity

Maximum no calves housed at peak

- 400

Month of peak use

- September

Age of calves entering and leaving shed

- 24 hours to 60 days

Labour requirements (total man hours per day at peak use)

- One person takes six hours at peak (not including fetching milk and new calves)

Labour hours per 50 calves at peak (total man hours/50 calves/day)

- 0.75 hours/50 calves/day

Other

- Lighting: Three metal halide globes used 24 hours per day at peak to encourage feed intake

-

Pen specifications

Pen structure

Type

- Group of 30 to 35

Wall height

- 1,000mm

Wall materials:

- Front: welded mesh on steel frame

- Sides: welded mesh on steel frame

- Back: zinc aluminium walls with 2m x 3m roller door

- Removable: Side walls swing back to wall and can be removed for cleaning

Other

- Gates on either side of calf feeding units

- Can drive ute to pens through central race for unloading

Pen flooring

Type

- Concrete and gravel covered with deep wood shavings

Drainage

- Drainage of concrete at nib wall, 2-3% slope on concrete to nib wall

Total floor space per pen

- 52 square metres

Floor space per calf at peak capacity

- 1.7m2

Other

- Feed and water kept on concrete area

Bedding

Type

- Pine post peelings (wood)

Minimum depth

- 150mm

Maintenance

- Completely replaced for each batch

Other

- Used bedding composted and used as mulch on neighbouring berry farm

Feed and water

Milk feeding system type

- DeLaval automatic feeding units

- 12 units servicing 12 pens

- One controller per four units (not networked)

- Calves fed up to 6L/day (2L every eight hours)

Milk delivery method

- Transported by 1,000L container to two refrigerated 3,000L vats in calf shed (milk lasts up to 30 days)

- Fed milk only: colostrum, antibiotic milk and sale milk if run out

Hay

- Hay racks in paddocks

Pellets

- Auto feeders feed up to two kilograms per calf

- Manually top-up feeders

Water

- Pig nipples in each pen

- Some paddocks have troughs

Other

- Hot water service, wash drum and chemicals

- Underfloor pipes to supply refrigerated milk to feeder units

-

Other infrastructure

Cleaning and disinfection

Type

- Batch

Other

- Sometimes batches follow each other (pens cleaned in between)

- Lime over gravel, formalin wash over concrete parts

Biosecurity

Access restrictions

- Shed door locked

- Gate locked to stop entry to area from public road

Housing of sale calves

- Housed in another separate shed on another property

Quarantine area for sick calves

- Separate pen made at end of shed

Other

- Closed herd but mixing calves from four different farms

Feed preparation and storage

Facilities

- Sink, fridge, storage cupboard, records/filing cabinet

Case study: Annie Gay, Shepparton, Victoria

Purpose-built – individual rearing for great growth and earlier weaning

Annie Gay of Coomboona Holsteins is based in Shepparton, Victoria. The farm's purpose-built calf housing system features 90 individual pens and eight communal pens with eight to 12 calves per pen. The system has individual and group pens inside the shed and group pens (each with an igloo) just outside of the shed.

The project cost more $50,000. Coomboona rears 1,000 calves per year in a year-round calving system.

In this video, Annie demonstrates her purpose-built shed, commenting on the benefits of individual pens and the hands-on approach it offers.

-

Shed specifications

Shed structure

Construction materials:

- Walls: colourbond

- Roof: zinc

- Floor: cement

- External yard: cement

Aspect

- Car park for the building faces the south wall

- Winds are predominantly from the south-west

Dimensions

- Structure: 30.32 metres long x 30.17m wide x 6.1m high

- External yard/calf paddock: Approximately 52m x 40m

Roof design

Pitch

- 7.5 degrees

Roof openings

- 10 x rotary ventilators (each 300 millimetres in diameter) located along peak in roof

Roof height

- Lowest point: 5.1m

- Highest point: 7.1m

Air space

Total air space

- 5,580 cubic metres

Air space per calf at peak

- 31.7m3

Ventilation

Type

- Passive, fan-forced

Cooling/airflow

- Sliding doors are located on all four sides of the shed

- Four sliding doors provide a maximum of 9.6m x 5.0m opening on the south and the north walls

- Two sliding doors provide a maximum of 9.6m x 6.0m opening on the east and the west walls

Shed capacity

Maximum number of calves housed at peak

- 176 (92 individual pens and 12 per group pen)

Month of peak use

- September to November and February to March

Age of calves entering and leaving shed

- Calves remain in the individual pens until 30 days old

- Then bulked in the group pen until about two months old

- Then moved into calf paddocks, each with an igloo, until they are weaned at about three months old or 110 kilograms live weight

- They then move into outdoor paddocks, each with a shade cloth for another month until they are finally moved to the nearby Coomboona farm

Labour requirements (total man-hours/day at peak use)

- 30 to 50 man hours per day

Labour hours/50 calves at peak (total man-hours/50 calves/day)

- 8.5 to 14.2 man hours/50 calves/day

Other

- The colostrum from each calving cow is tested for quality and graded as A or B, after which it is frozen for long term storage

- Each new-born calf is given colostrum(2–3 litres per calf at birth followed by another 2–3 L/calf within 12 hours of birth) via a nursing bottle prior to being moved into the calf shed

- Each calf is given a probiotic paste for their first three days of rearing to improve their immunity and digestion

-

Pen specifications

Pen structure

Type

- 92 individual pens, each 2.5m deep x 1.1m wide x 1.2m high, with solid plastic walls between pens

- Eight group pens, each 10m deep x 6.5m wide with additional area 7.1m x 6.0m outside the shed for morning feeding

- Eight calf paddocks, 52m x 40 m, each with an igloo

Wall height (mm)

- 1.2m height between individual pens

Wall materials

- Individual pens

- Front: mesh, permanent

- Sides: solid plastic, permanent

- Back: solid plastic, permanent

- Group pens

- Mesh/gates on front, sides and back

- Back opens onto outside yards via a large sliding door

Outdoor calf paddocks

- Trees are planted along the fence lines between calf paddocks to provide shade

- Each paddock has an igloo for protecting the stock against weather extremes

Removable

- Side walls swing back to wall and can be removed for cleaning

Other

- Individual pens are in batches of eight to 12, separated by alleyways (from 2.2m to 3.4m wide), for ease of access for feeding and cleaning out each pen

- The shed has been built to minimise contact between individual calf pens, to maintain high biosecurity for Johne's Disease, hence the use of high-grade plastic at the back and side of each pen

Pen flooring

Type

- Concrete throughout the shed and the outside section of the group pens

Drainage

- Each individual pen slopes to the front of the pen (away from the bedding) then into a spoon drain which runs along the middle of the alleyways

Total floor space per pen

- Individual pens: 2.75 square metres

- Each group pen: 65m2 inside the shed and 42.6m2 outside the shed

- Each calf paddock: 2,080m2

Floor space per calf at peak capacity

- Individual pens: 2.75m2 per calf

- Group pens: 5.4m2/calf inside and 3.5m2/calf outside at 12 calves/pen

Bedding

Type

- The back half of each individual pen is covered with about 110mm of wood chips (to facilitate drainage) overlain by 110mm of sawdust (for comfort)

- Each group pen also has an area (approximately 3m x 2 m) of wood chips and saw dust

- The front half of each individual pen has a large rubber mat

- The rest of the group pens do not have any bedding material over the concrete floor, for ease of draining effluent

Minimum depth

- 110mm of wood chips overlain by 110mm of saw dust in both the individual and the group pens

Maintenance

- The bedding in each individual pen is topped up as required and cleaned out when each calf is moved into the group pens

- Bedding in the group pens is periodically topped up then removed completely when each batch of calves are moved to the calf paddocks

Other

- Soiled bedding is discarded in a nearby bunker and eventually used for fertilising pastures

Feed and water

Milk feeding system type

- Calves are only fed calf milk replacer, which contains 22% fat and 28% protein

- It is fed via teats for their first 10 days in the individual pens, then via buckets for the rest of the time

- In the group pens, calves are fed calf milk replacer via large drums (inside during inclement weather) or via a stainless steel trough when fed in the outside yards each morning

- Trough feeding is also used while in the calf paddocks

Milk delivery method

- The calf milk replacer is mixed in an old milk vat then distributed to each pen via a tank and pump on a trailer towed by a small tractor

- To minimise the possibility of feeding into the wrong bucket, each individual pen has three buckets of different colours attached to the front of the pen: a red one for calf milk replacer, a black one for water and a green one for calf meal

Hay

- Hay is offered to each calf only in the group pens and calf paddocks

Pellets

- Calves are fed a formulated grain mix while in the individual pens and another formulated grain mix while in the group pens

- Bull calves are fed formulated calf pellets in the group pens

- The calf meal fed in the individual pens contains 20.8% protein and 13.3 megajoules per kilogram of dry matter of metabolisable energy

Water

- Water is freely available in buckets in each individual pen

- In large drums in the group pens and calf paddocks

Other

- Calves are fed 4 litres per day of calf milk replacer (twice daily feeding) for one month while in the individual pens

- Followed by 4L/day (once daily feeding) for a second month while in the inside group pens

- Followed by 5–6 L/day (once daily feeding) for their last month of milk feeding while in the outside group pens

-

Other infrastructure

Cleaning and disinfection

Type

- Batch

- Disinfectants/sanitisers are routinely used for sterilising all equipment used for feeding calves

Biosecurity

Boot/hand washing facilities

- Routine

Access restrictions

- Routine

Separate clothing/boots

- Routine

Housing of sale calves

- Sick calves are kept separate from the healthy calves and their feeding equipment (and pens) is cleaned last each day

- Staff use a separate set of disposable gloves when attending to each sick animal

Quarantine area for sick calves

- See above

Other

- All calf records are kept in a folder for ease of access and also stored electronically

- There are a series of standard operating procedures clearly available to calf rearing staff

- Each row of individual pens has a whiteboard for recording specific daily observations and staff instructions

Feed preparation and storage

Facilities

- Formulated calf meals and pellets are stored in a silo

- Calf milk replacer is stored in 20-kilogram bags